EDITORIAL

Aftermarket Bottom Brackets with DUB Cranks?

I didn't intend to solve a problem when I started tinkering, because I wasn't yet aware a problem existed. At that point I just wanted to see if I could make an Enduro Bearing 30mm bottom bracket, that I already had tucked away in a drawer, work with a DUB crankset. I went to the web and found a couple of results for products to shim a 30mm inside diameter bearing down to the required 28.99mm to fit a SRAM DUB spindle. The Enduro Bearing PF92 BB has double row angle contact bearings that should be very durable, and I don't currently have a bike or cranks requiring a 30mm bottom bracket, and I wanted to put it to use. I hate it when products become prematurely obsolete, so I was on a mission.

I didn't need to change out the DUB bottom bracket I'd been using, I just wanted to see if it was possible to hack the system and find another solution .

The first Google result was from Chris King but it's stated that this solution is made to sleeve their own bottom brackets down to 28.99. I figured it would probably work fine with the Enduro BB, but I also found something from a Taiwanese company I'd never heard of; AEROZINE TW. Chris King's solution was 22 USD and Aerozine's was 6 so I went with door number cheap. After I purchased it online they emailed me saying they'd also need 23 bucks for shipping, so it was likely to be a wash, but I was committed at that point.*

*TBF when I told them I'd be writing about their product, they waived the shipping fee.

I'd been testing GX AXS and I wanted to go back to the XO1 version to see if I could notice any difference (I couldn't) and I decided to swap the cranks at the same time, because I'm not yet a fully recovered weight weenie. Unfortunately, my excellent Enduro BB tool doesn't work with 28.99mm so I used the hammer and punch method to remove the DUB bottom bracket that I've been using for the better part of a year. I managed to get one side out undamaged but I bodged the other side so it would no longer spin freely. The undamaged side was in excellent shape and both sides were still well-lubed; a considerable testament considering how aggressive I am with my spray nozzle, which I set to 'destroy' after almost every ride.

A more conscientious mechanic would clean the bike before performing this task, but I got lazy.

What I didn't know at that point was that DUB bottom brackets, at least on this side of the border, were becoming as rare as frankincense. Canadian retailers can't order SRAM or Shimano parts from across the border, neither directly from SRAM or from any distributor and the best news I've heard, from Lou Costa of Obsession Bikes here in North Van, is a September 15th delivery for popular sizes. That doesn't mean there won't be other orders trickling in during that time, it just means, according to Kevin Calhoun, who works for Hawley Lambert, a distribution company that trades on both sides of the 49th parallel, that you won't be able to place any additional orders until that time. If a shop booked those parts months ago they may very well be arriving this month, but they are likely all spoken for. Now my tinkering had purpose.

The Aerozine adapter with the plastic DUB shim I inadvertently dislodged from the DUB bb. Different materials aimed at the same result, but SRAM's solution is backed up by thousands of hours of testing conducted by professionals using the most sophisticated and up to date technology available. Also note the blue o-ring in the SRAM sleeve, designed to keep moisture out. The aftermarket sleeves do not address that issue.

In the process of removing the DUB BB, I dislodged one of the plastic sleeves that keeps the DUB system from running the aluminum spindle against the stainless steel inner race of the bearing, and this got me wondering. I had a long conversation with SRAM drivetrain product manager Roberts Graudin when DUB was introduced, but I never thought to ask him about bearing sizes. I assumed at the time that the rationale for a 28.99 mm spindle was to accommodate a larger bearing. In fact it was to allow for the aforementioned plastic sleeve. Shimano bottom brackets use a 24mm spindle but they run on bearings with an inner diameter of 25mm, and they too use a plastic sleeve to prevent a metal on metal interface between bearing and axle. Other manufacturers, Raceface and Chris King being a couple of noteworthy examples, have no qualms about this, but there are some good reasons to provide this plastic buffer.

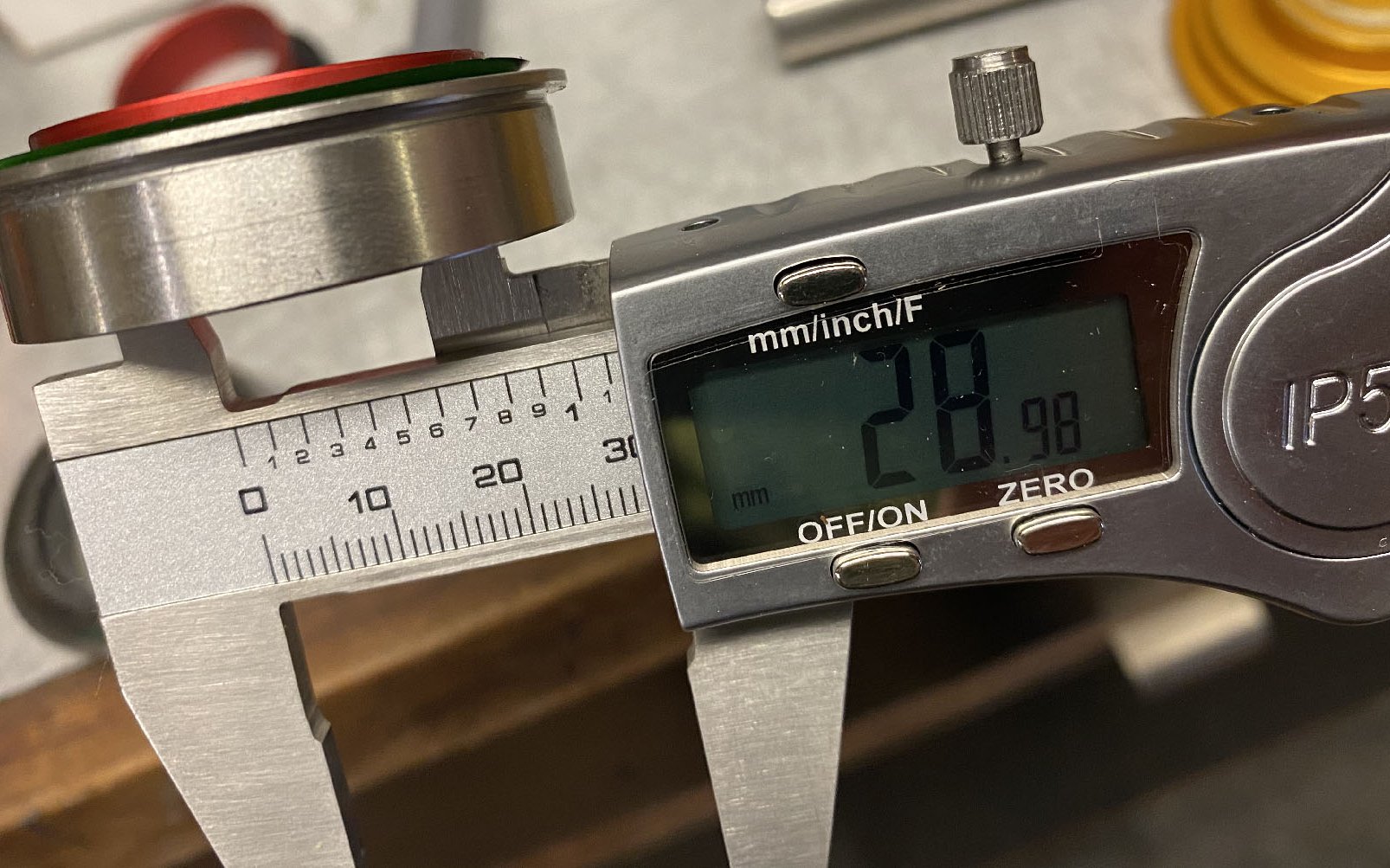

I can confirm that SRAM's claims that their system is just shy of 29mm are legit Just the right size to accept a spindle that measures 28.99 mm. This is the DUB cup I had just removed.

Here is the AEROZINE TW aluminum shim within an Enduro 30mm PF86/92 bottom bracket bearing. That number works too.

When exposed to moisture, the mixture of aluminum and steel can produce galvanic corrossion. That is asssuming there is wear on the aluminum to remove protective oxidization, and corrosion is much less likely when paired with stainless steel, as in this case. Another factor is that aluminum and steel expand and contract at different rates as temperatures change. Clearly in a perfect world they are best kept apart to prevent creaks and groans which was one goal of the slightly narrower spindle. The sleeves also have an o-ring which improves sealing. Since I've been riding DUB, I haven't had a creaking crank or any bottom bracket issues, but my stuff comes apart regularly to be inspected and cleaned as I roll through test parts, so I'm not a good sample for that evidence.

A bonus about using a regular 30mm bearing, without SRAM's plastic shim that isn't designed to be removed by the user, is that I was able to use my Enduro Bearing press. It's a beautiful tool that makes pressing in or removing a bottom bracket a pleasure. You can now buy a DUB version that's reverse compatible with 30mm bearings.

After taking apart the DUB bottom bracket, it was time to conduct an investigation. When I saw the measurements on my calipers I thought I'd uncovered a dirty secret; SRAM's been using 30mm bearings all along! Fortunately, it wasn't a secret at all, SRAM just kept that info a bit quiet for obvious reasons during the screams of 'another fucking new STANDARD!' Once I recovered my composure, I realized that getting a couple of tiny aluminum shims sent from Taiwan wasn't necessary at all. If you're careful, you can remove SRAM's plastic sleeves and reuse them on other bottom brackets, or some at least. The Enduro bearings with their double row of angular contact bearings were slightly wider and the inner flange didn't make it past the inner edge of the bearings. If you removed the inner flange of SRAM's plastic shims with an Exacto knife they would work fine, but I was too deep to turn back.

Pressing in the new cups.

Very little pressure is needed and the precision of the tool makes everything line up easily.

Thankfully I could use the Enduro PF86/92 installation and removal tool, which makes the process a pleasure, to press in the new bearings. When I'm working with a 30mm ID bottom bracket I actually look forward to any install or removal because it's so slick. Enduro also makes an adapter for DUB which is reverse compatible with 30mm bottom brackets. Once the cups were pressed in the rest was routine. I omitted the recommended spacers on the drive side to improve my Eagle chainline, and then installed the cranks, with a steaming glob of fresh grease applied to the aluminum spindle.

Before I go any further I need to tell you what SRAM feels about all this. I was told by Chris Mandell, SRAM's North American PR honcho, that it's important to understand that all the testing behind DUB in terms of durability, strength, and sealing apply only to DUB as a system. If you can imagine something that could happen to a set of cranks, including the load from a massive and unintended drop to flat, hundreds of thousands of loaded revolutions, side loads etc., SRAM has tested for these eventualities and built a system that exceeds the strength and durability of anything they'd made previously, all at lower weights. This system is apparently more interdependent than before, and the result is, "better wearing, higher performing products."

Once the cups are in place, the aftermarket sleeves just slide in. Voilá! 28.99!

SRAM is confident that, when using a DUB bottom bracket with a DUB crank, you are getting the safest, most durable system possible. Once you start messing with that system, that confidence is gone. It's possible that axles will break prematurely, interfaces will creak, and all hell will break loose. After years of being able to mix and match cranks and bottom brackets without any real problems, I asked Mandell how he'd feel about riding a DUB crankset with a bottom bracket from another manufacturer. His reply was; "I wouldn't be comfortable.' His advice is to spend the time to call a few shops and source a genuine DUB BB, and if you're able to do that you're likely to save money and, it seems, get much of the performance and longevity SRAM is claiming.*

*Based on my intel talking to a few mechanics at different shops, this is legit, aside from some early DUB BBs that had premature wear issues.

Re-DUBed and ready to go, sort of. I haven't had any problems with my hacked non-SRAM solution yet, but TBF it's early days.

Consider yourself warned. I haven't had any problems, and my Enduro Bearing/AEROZINE solution has been running silently, but it's only been a couple of weeks. I will update this article if things go to shit, but I don't share SRAM's fear that this system will cause issues with longevity and performance, and personally I'm pleased that some aftermarket solutions* exist considering how the pandemic has affected global demand and supply for the entire bike industry.

*Aside from Chris King and Aerozine TW, Wheels Mfg. and Enduro Bearing make solutions to adapt their bottom brackets for use with DUB cranks, or you can try reusing SRAM's plastic sleeves with the correct size 30mm bottom bracket for your frame, which SRAM doesn't recommend either

Comments

Perry Schebel

2 years, 9 months ago

waaait, is this andrew posting under cam's account?

Reply

Karl Fitzpatrick

2 years, 9 months ago

I had assumed who the author was and had to scroll back up when I realised it was a yeti in the pics...

Reply

Sanesh Iyer

2 years, 9 months ago

Those enduro BBs are awesome. I usually burn through 2 OEM BBs a year. I have that exact Enduro BB and it's been going for 4 years. You can tell it's not new anymore, but it has many revolutions and hucks to flat.

Reply

DMVancouver

2 years, 9 months ago

Mine is 2 years old and spins like the day I bought it.

Reply

Mark Forbes

2 years, 9 months ago

Just installed one on my Yeti SB 5.5 this week. The cheap previous bearings were nice and crunchy, so I decided to spoil my bike.

Reply

Thunderbear

2 years, 9 months ago

Ha! I discovered this as well last fall! I used the DUB plastic cups in a RaceFace BB for a while, worked just fine although it didn't seal perfectly. Great emergency solution.

I think the reason for the reliability of DUB BBs is in the seal. Bearings wear out because of water ingress, not use.

Reply

AndrewR

2 years, 9 months ago

The BB Infinite bottom bracket PF92 DUB also uses 30 mm bearings and a polymer sleeve.

https://www.bbinfinite.com/products/bb92-for-dub-29mm-mtb-crank-sets?variant=31626434871429

I realised this when I ordered one for my XX1 DUB crank and one for my Canecreek eeWings crank. Same shell, same bearings but the DUB version had the inserts.

They also sell the inserts as replacement parts: https://www.bbinfinite.com/products/dub-bearing-inserts-service-part-pair?variant=21140415414331

And I can attest that their quality is insanely high (ie let's aim for perfect and deliver that to the customer).

They also have excellent customer service which is a bonus.

Reply

Thunderbear

2 years, 9 months ago

Nice! I do wonder though how important the blue o-ring is to prevent water ingress, as compared to just an aluminum or plastic sleeve. It might just be the key to longevity of DUB BBs.

If (when) water gets pulled in between the axle and sleeve by capillary action it will just sit there in direct contact with the bearings and protected from evaporating.

I suspect the same mechanism is wreaking havoc on headset and pivot bearings, when water gets trapped and the bike sits in a cold garage.

Reply

AndrewR

2 years, 9 months ago

This comment has been removed.

Mammal

2 years, 9 months ago

I've only had my DUB BB for a year now, but I've never had a BB run so smooth after a year. And it was subjected to some serious miles, tonnes of slop, and even left out overnight in the rain a few times.

I feel it's a shame that a perfectly good, extremely durable BB needed to be ruined in order to fit a perfectly good, extremely durable BB, but I guess that's all a part of the "science".

Reply

Cam McRae

2 years, 9 months ago

I agree completely and it certainly wasn't my intention. I was just a little sloppy with the removal. I may be able to make it serviceable again and I'll do my best to make that happen, particularly considering the shortage that exists currently.

Reply

Skooks

2 years, 9 months ago

Great information Cam, thanks. As a long-term bike tinkerer this is gold. Having access to a lathe at work means I can machine my own shims. I have been impressed with my dub BB. Been running it for 1.5 seasons of regular shore riding and it is only now starting to develop play. Still spins smooth though. I strongly prefer thread in BB for ease of maintenance, especially after seeing the tooling you need to service press fit properly.

Reply

Eric Van Sickle

2 years, 9 months ago

I guess the value of the new Dub BB I’m about to remove and sell just went through the roof!

Reply

Sean_D

2 years, 9 months ago

What type of bearings are used in SRAM's DUB BBs? Since one of the OEM cups has already been damaged, perhaps a tear-down is in order. I'm curious as SRAM made big claims of increased durability when they released the new DUB "standard".

Reply

Cam McRae

2 years, 9 months ago

Happy to pull it apart and see what I can find but my understanding was they were using proprietary bearings. We now know this is a common size rather than something unusual however. I'll see what I can dig up.

Reply

Luix

2 years, 9 months ago

Aerozine BB solutions are durable and well made in my experience (not saying they're Chris King quality, but they're decent). I've been running a couple of external BSA to BB30 conversion cups for over 3 years now. The original bearings it brought were crap straight out the box, but for $21 shipped while also sporting the proprietary BB wrench it was well worth the money.

Once some Japanese bearings were thrown in, the darn thing has been spinning awesome (with regular regreasing 3-4 times a year) since it was assembled. Also, the dimensions were bang-on. I merely had to take away the play adjust assembly from the frank's axle and it all fitted in the first try.

Reply

Andy Eunson

2 years, 9 months ago

My DUB press fit in my Trek has been stellar. I’ve never had a threaded bb last over two seasons. Mine is still smooth and silent. Good to know when I need to replace it that there are aftermarket options.

Reply

Ride.Doc

2 years, 9 months ago

Anyone on the North Shore or Vancouver area have a good source for bearings? Replaced the 6 or 8 bearings on my intense this winter, and was literally advised by the guys in Cali to source my own bearings... which is turns out was aliexpress in my case, so I'm anticipating another replacement in the near future!

Reply

Cam McRae

2 years, 9 months ago

Here's a local source for bearings.

https://reciprocators.ca

Reply

Ride.Doc

2 years, 9 months ago

Wicked, thanks Cam!

Reply

DMVancouver

2 years, 9 months ago

This comment has been removed.

MuscogeeMasher

2 years, 9 months ago

The day I give SRAM money for a BB will be before, but not that much before, the day I give CrankBrothers money for anything, other than maybe a multitool. However, absolutely love my Codes and my Guides and my eagle drive trains are pretty darn good.

Reply

Pete Roggeman

2 years, 9 months ago

Well, I can understand your hesitation, but a lot of us have had really good results with DUB BBs, and if you search CrankBrothers over the last few years on our site - Andrew Major, in particular, has tested their stuff really long and hard and with a critical eye - you may be surprised at how much things have changed.

Reply

Velocipedestrian

2 years, 9 months ago

I'll stick with my 24mm shimano spindles. But a shout out for the hand tool - I've been flouting the 'do not disassemble' label and pressing fresh bearings into threaded cups for years. It's the bees knees.

Reply

Michael

2 years, 8 months ago

@Cam can you please ask your SRAM contacts to allow us poor dirty Canadians to order their products from US online retailers?

Reply

David Guinane

2 years, 1 month ago

Does this mean you could buy a 30mm spindle crank, remove the plastic sleeves, and fit the crank to a DUB BB?

Reply

Powking

1 year, 3 months ago

@Cam. I also want to know this. This would solve a bunch of things for me!

Reply

YvanCB

1 year, 1 month ago

@Cam

Hello,

Your experience is very very interesting. SRAM uses bearing with an internal diameter of 30mm; they are jokers!

Therefore, can you tell us if there a spacer between the 2 Enduro bearings? I think it could clever to install one to avoid moisture to enter in the bearings by the inside of the bike's frame.

Regards.

Reply

Please log in to leave a comment.