Enduro XD-15 TorqTite Bottom Bracket

Jewelry For The Muck

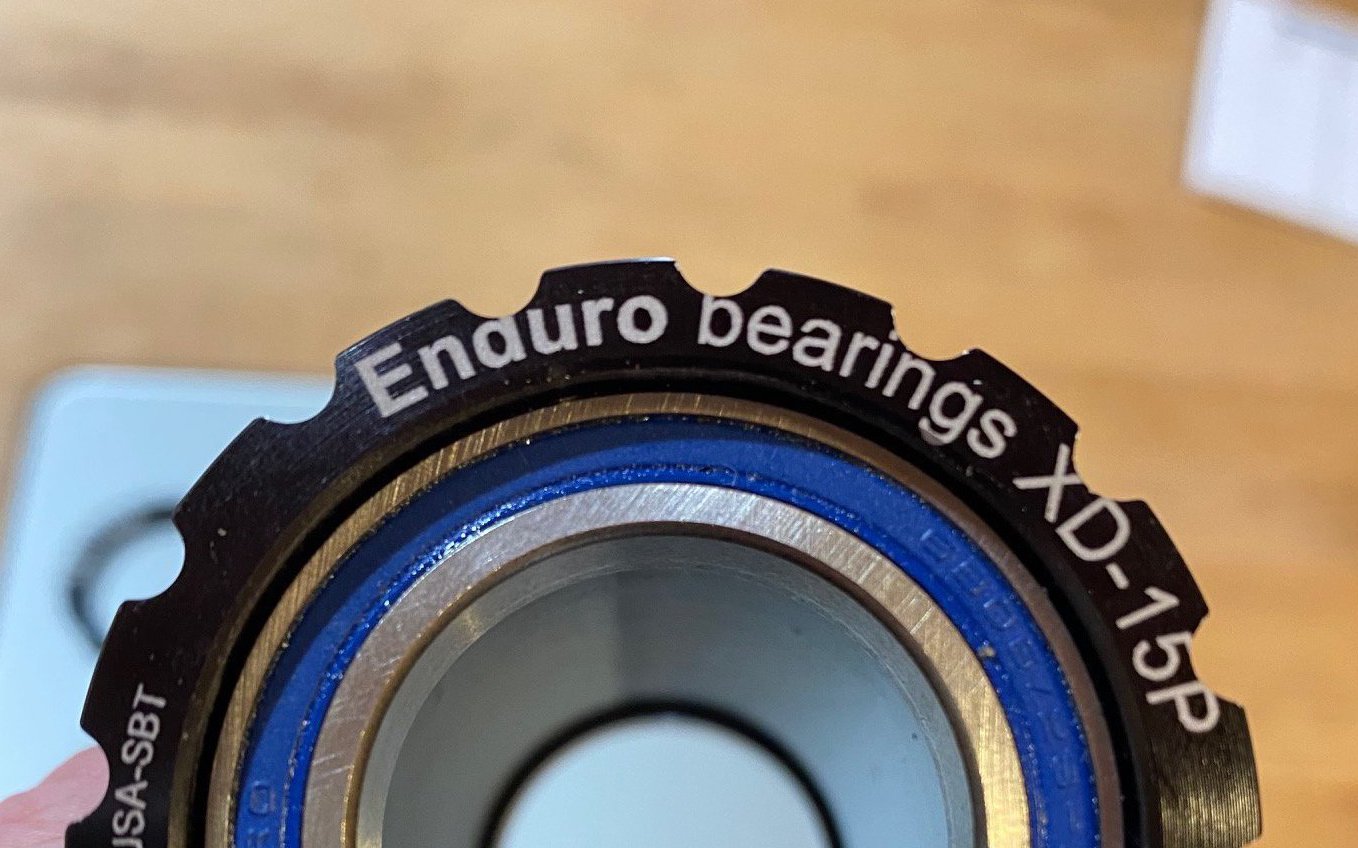

Enduro TorqTite XD-15 bottom bracket.

MSRP: $229US

Maybe I should have titled this "Does a bottom bracket really warrant 1100 words before it's even installed?"

Right up front, I am going to admit that there seems to be something elementally wrong about installing very expensive, beautifully machined, high precision bearing assemblies down in the gritty purgatory that sits between the cranks of a mountain bike. However, there also seems to be something elementally wrong about manufacturing a highly evolved, beautifully designed, painstakingly laid-up carbon fiber frame and then making the bottom bracket hole a press-fit. It’s an affront to my aesthetic sensibilities, and an insult to my inner mechanic.

Which brings us to this little problem solver here: Enduro’s TorqTite bottom bracket designed to fit inside a BB386 sized hole and keep a set of 30mm cranks spinning happily. In this case, I opted not only to de-press-fit my frame, but I decided to see if Enduro’s XD-15 ceramic bearings are worth the substantial scratch required to purchase a set. So, this will be something of a long term review. But, like all long journeys, you gotta start somewhere. In this case, let’s start a couple “Why” clauses.

Soooo, $229 and 123 grams. That's, ummm, one dollar and eighty six US cents per gram. Not cheap. But still about a quarter the price of an equivalent amount of good weed, for the sake of comparison.

Why do I hate press fit bottom brackets so much?

I don’t hate them. Hate’s a very strong word. Done right, a press fit bottom bracket can save valuable weight and space. But “done right” is apparently open for some pretty broad interpretation. If things are not dead nuts perfect in every sense of alignment and sizing, then press fit bottom brackets can be creaky, problematic, recurring nightmares. And while I may not hate press fit bottom brackets, I absolutely loathe creaky bottom brackets of any type. My experience has been that sooner or later, almost every press fit BB is going to start making some ugly noises.

In the case of the bike that this little Enduro gem is destined for, the bottom bracket hole looked pretty well designed, and the OE bottom bracket went in smoothly enough. After the first few break in rides, things were working just fine. But the assembly of the bike had left me less than stoked. Delrin cups, pressed into a carbon fiber frame, with the instructions calling for a generous slathering of silicone RTV to hold it all in place. I use silicone RTV on car windshields and the high-temp version on poorly designed motorcycle exhausts, and every time I crack a tube of that stuff open, I don’t feel like I am enacting a robust or long lasting solution. I feel like I am one small step removed from bailing wire and duct tape. It just seems wrong to use it to install a bottom bracket in the part of a bike that sees the greatest uneven load cycles and the harshest environmental abuse.

In the face of my grim assessment, TorqTite to the rescue! An aluminum drive side cup necks smoothly up to fit snugly into the BB386 sized hole. There’s a similarly proportioned non-drive side cup that has an aluminum sleeve with a stepped collar threaded onto it. Threads on the other end of the collar then screw into the drive side cup and the whole assembly sucks together nice and tight, using the thread tension to pull the cups into the frame and torque down cleanly and hopefully creak-free. No RTV required. It is elegantly simple, cleanly machined, and it feels almost criminal to make parts this pretty go sit invisibly in the bowels of my bike. Enduro is not the only choice when it comes to this kind of retrofit bottom bracket, but nobody else is claiming to have a ceramic bearing running in a super-hardened race that actually gets smoother with time, and is basically impervious to contaminants. Seems too good to be true, right? This brings us to “Why” number two.

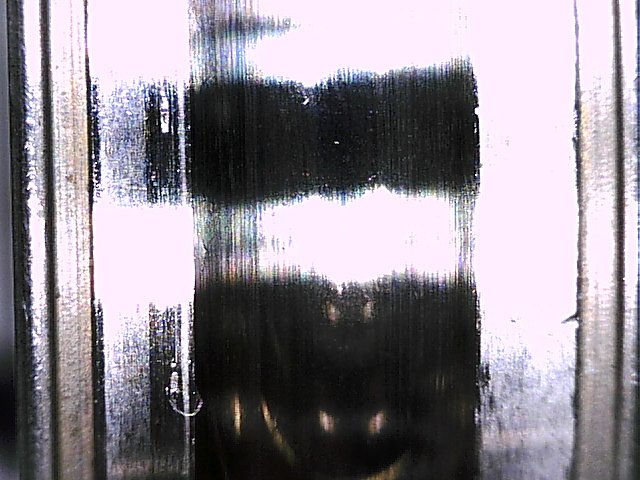

This is a super-magnified image of an Enduro XD-15 race after 20 hours of continuous testing at 120rpm, with a radial load of 160 pounds and an axial load of 65 pounds applied. Shiny and smooth, no galling visible, race appears mirror polished.

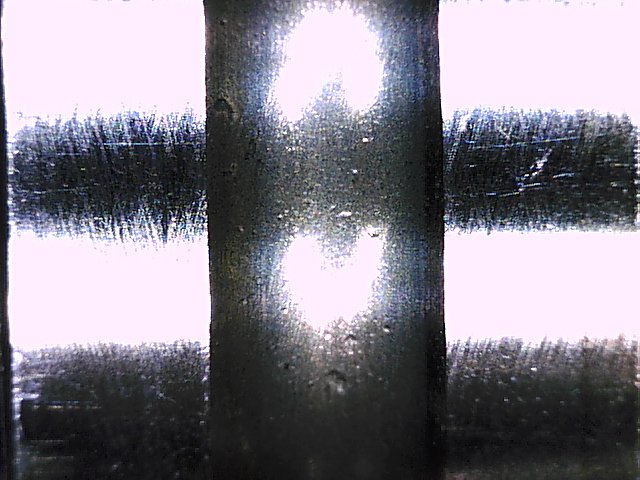

And this is an image of "some other fancy bearing" after the same testing period and same loading. Note the galling appearing in the race. Also, note the narrower and shallower bearing track. Enduro opts to use larger balls across the board than its competition, claiming that larger diameter ball bearings can withstand much greater punishment with less likelihood of pinching, jamming, chipping or exploding. More info about how and why Enduro tests bearings can be gleaned here

Why would you go to the expense of installing ceramic bearings in a bottom bracket when they’re just gonna get eaten by the world anyway?

Ceramic bearings are easy to look at as needless expense. The kind of thing that roadies like to waste their money on while buying oversize jockey wheels. The claims are always about reduced friction and precision, but even steel ball bearings are capable of insane levels of precision these days, so that leads to what makes ceramic awesome. And what makes ceramic so awesome is its hardness. Ceramic balls are ridiculously tough. So tough that ceramic balls and just the right amount of grit can tear the bejeezus out of most hardened steel bearing races. Which, in the end, is not really any better a scenario than your usual shitty weather bearing failure.

XD-15 is the name of the steel used in the races of this bottom bracket, and it is not the same as other hardened steels. It’s a nitrogen infused steel alloy initially developed for use in airplane wings, where a primary concern was corrosion caused by de-icing compounds. It’s insanely expensive and something of a pain in the ass to work with. Too tough to pull through mandrels and form into tubes, XD-15 bearing races are machined into inner and outer shape from rod stock, then heat treated on ceramic tables, then cryo-treated down to close to absolute zero, THEN given three separate black oxide coatings. All of these treatments normalize the grain structure of the bearing race. The black oxide coating is then removed from the race where the bearings will roll, Japanese ceramic balls are inserted, Klüber Isoflex grease is spooged into the bearing, silicone seals are slapped into place, and off to the races (ha!) we go. This is what Enduro does. They make bearings, which is a lot more of a pain than buying someone else’s bearings and etching your logo onto the outside.

Enduro is so confident that this combination of ceramic balls and XD-15 races will not only resist wear, but actually get smoother with time and use, that they back these with a lifetime warranty.

So, that’s why I am installing this bottom bracket.

But still, damn, that’s a lot of money. I could buy five of the press-fit BBs that I am replacing for the cost of this. And a lifetime warranty, while cool, might not be worth a whole lot if I decide to unload this bike in a couple years. However, the idea of a bottom bracket that straight up outlasts the rest of the bike has a perverse appeal, so I’m going to see what happens.

Meanwhile, if you’re looking to shore up a creaky press-fit hole in the bottom of your bike, but don’t want to shell out for the Eternal Flame ceramic option, Enduro offers the same bottom bracket with some very sweet 440c bearings for a substantially less wallet-staggering $149.

Why on earth is there a picture of Johann Museeuw competing in the 1994 Paris-Roubaix here at the tail end of a way long piece about a ceramic bearing posted on a Canadian mountain biking website? Well, one, because it's a rad shot (poached from a random internet forum but shot by the insanely talented Graham Watson). Two, it's Johann Museeuw. There can be no upper limit for pictures of Johann Museeuw doing the business at Paris-Roubaix. Three, check out that bike! Bianchi full suspension road bike made specifically for Paris Roubaix that year. Enduro Bearings co-founder Matt Harvey designed that bike. James Huang wrote a pretty cool piece for bikeradar a couple years ago that includes some of the story about the agony and ecstasy of the bike that Matt designed. It's worth a read... But suffice to say, Matt has had some time to contemplate how we use bearings in bicycles.

Comments

hairymountainbeast

1 year, 11 months ago

…so, for $229 I can get bigger AND tougher balls!?!

Reply

Vik Banerjee

1 year, 11 months ago

I'm glad there are products like this for folks stuck with PF frames for one reason or another. That said I'd just eliminate them from consideration when buying a new frame and save myself the trouble.

Reply

Mike Ferrentino

1 year, 11 months ago

Well, there's that. In this case everything else about the bike in question ticks the boxes (disclaimer, it's a gravel bike). My only real complaint was the press-fit, and I knew there was a way around it. I'll wait to see if/when the crows come home to roost on this one.

Reply

Vik Banerjee

1 year, 11 months ago

If the only acceptable frame I found when I was looking to buy new was PF I would do what you are doing Mike or at least be prepared to at some point down the road if the BB gave me issues. That said I haven't yet found myself limited to only one choice that was PF when looking for a new bike.

Reply

fartymarty

1 year, 11 months ago

Mike, you're really living in the wrong part of the world to be long term testing this. You need to move north of the border or across the pond where you have to jet wash your bike to get the crap off. I've just put a Hope BB in my bouncy bike and will be intetested to see how long the bearings last. At least they are replaceable.

Out of interest have you (or any readers) tried stainless steel bearing for pivots? I'm thinking of installing a set in the Murmur in March when I replace the current ones (Enduro steel bearings). From memory SKF are 2x the price of steel bearings however in my mind less likely to rust therefore should last longer.

Reply

kcy4130

1 year, 11 months ago

Stainless bearings have a lower load rating than steel. This may or may not matter, depending on if the bearing used on that frame are oversized sufficiently or not. If your Murmur goes thru bearings (for reasons other than water/dirt ingress) then ss bearing might be a bad idea.

Edit: Actually, stainless might wear faster from dirt/sand ingress than steel as it's less abrasion resistant.

Reply

fartymarty

1 year, 11 months ago

I think it's from dirt / water ingress. Only one way to find out I guess - it's £40 v £20 for the cost of stainless steel so worth a try. Worst case I have to pop some steel ones back in.

IIRC Chris King use stainless bearing in their hubs / headsets / BBs.

Reply

kcy4130

1 year, 11 months ago

Yeah, nothing wrong with stainless bearings in general if the hub or whatever has been designed to use a size of bearing large enough the have sufficient load rating. You might email Starling and ask. Just a thought. I mean, a bearing failure could possibly cause damage to the shock and even the frame.

Reply

Mike Ferrentino

1 year, 11 months ago

I would try to protest your salient observation, but you're right. This part of California is not really a good place to test for the kind of environmental carnage this bearing needs. I am going to mix this up and use a ceramic bearing on one side and a standard 440c on the other and see with time if one gets rougher than the other. And if it ever rains, I will consider that an excuse to ride as opposed to the usual "I'm melllllltiiiiing" run and hide from the weather approach. However, for the sake of reference, I think Hope are speccing Enduro bearings these days (but probably not the ceramic ones).

Reply

NealWood

1 year, 11 months ago

I suspect that the loads on the drive and non-drive side of the BB are not equal. It might not be a fair test to put one brand bearing on one side and another on the other side.

Reply

Velocipedestrian

1 year, 11 months ago

Shimano BBs historically die NDS first for me. I wonder what the factors are...

Reply

Jackward

1 year, 11 months ago

I would guess it’s possibly to do with what foot forward you descend with and the extra force that will constantly apply to one side. Are you a left foot forward rider?

Reply

Mike Ferrentino

1 year, 11 months ago

I'm not so sure that bb bearing death is attributable to loading one side more than the other - seems to my mind that uneven loads would get transferred relatively equally across such a short distance via such a stiff spindle. However, the chainring and drive side crank spider might to shield a certain amount of muck from direct ingress to the bb. Pure speculation on my part. I'm a caveman, not an engineer.

Reply

kcy4130

1 year, 11 months ago

I'd just like to point out that being a caveman and being an engineer are not mutually exclusive. If I've proven anything in my life/career it's that one can be both.

Bogey

1 year, 11 months ago

Exactly Mike. BB bearings generally fail from corrosion and not from any sort of loading imbalance or overload. The NDS cup gets more grit and water from riding and cleaning so it won’t last as long.

fartymarty

1 year, 11 months ago

Mike - I jest about your lack of mud. I'm very much jealous of your year round dust. If we're lucky we have a few months of dust.

It will be interesting to read about your findings on ceramic v standard.

I'm pretty sure Hope hubs come with Enduro bearing. I'm not sure on their HS and BB. I need to take a look next time I have the forks / cranks off.

Reply

Andrew Collins

1 year, 11 months ago

The OEM Hope bearings are awful. Budget to replace them with quality NTN or SKF bearings.

Reply

fartymarty

1 year, 11 months ago

Thanks for the heads up, will keep an eye on them.

Reply

hongeorge

1 year, 11 months ago

Nah, I've had great life out of multiple Hope BBs, their bearings are top notch, and I ride in absolute slop nine months of the year

Reply

NotMeAtAll

1 year, 11 months ago

I still have a question. You know, aluminium and carbon doesn't play nicely. How one prevents galvanic corrosion when installing aluminium cups? Is the anodization enough? grease, carbon paste, copper paste, whale oil, any other alternatives to prevent the demise of the frame?

Reply

Mike Ferrentino

1 year, 11 months ago

I needed to clarify a couple things before responding to this. Technically, galvanic corrosion shouldn't be a problem with an anodized cup. You need an actively corroding material for galvanic corrosion to occur, and one of the reasons to anodize aluminum is to ward off that. That said, provided you use a grease plays nice with carbon fiber, it's a sound idea to install with a thin film of something. Aside from an extra layer of potential protection against the elements it also helps the pieces squeeze together nicely.

Reply

cyclotoine

1 year, 11 months ago

The Enduro bearings in my Wheels MF threaded BB are still good after three and a half years including periods of time on the BC coast in winter and three months living on the back of a van in New Zealand. I actually pulled that bottom bracket from the bike when I sold it last summer as I wanted to keep the RF turbine cranks and the cranks going on required a different BB. So I have it spare sitting in my shop.

Reply

JT

1 year, 11 months ago

Curious how removal works out. Obviously threading the pieces together pulls the cups into place, but does it work the same on removal? If one cup has a slight bit more snug fit than the other, does it result in it staying in place while unthreading the BB. If so, it only partially addresses one of the issues it's supposed to help prevent.

Reply

Mike Ferrentino

1 year, 11 months ago

Not sure. I have a wonderful assortment of hammers though, just in case...

Reply

Deniz Merdano

1 year, 11 months ago

We need a MF shop tour...

Reply

Mike Ferrentino

1 year, 11 months ago

The "shop" has for several years now been an ongoing experiment in embracing chaos theory. It is an embarrassing mess.

Reply

Deniz Merdano

1 year, 11 months ago

There is charm in embarrassing messes. I can only imagine the coolest shit you have hanging off of the most random peg somewhere in plain sight...

Reply

Mike Ferrentino

1 year, 11 months ago

This comment has been removed.

Kenny

1 year, 11 months ago

When you unthread it, one side will come out like you say. Then thread it back in a few threads and hit it with a mallet to knock the other side out. Easy.

I used the wheels mfg thread together setup on a couple press fit frames (looks almost identical to Mike's enduro setup in the article) and it was super solid. I think the thread together system is absolutely the answer for any press fit frame.

Reply

mrbrett

1 year, 11 months ago

You had me at "Klüber Isoflex grease". That's some good stuff.

Reply

Moritz Haager

1 year, 11 months ago

I think there is a lot to be said for a long lasting BB. Sure, you replace a cheap BB several times for the price but 1. Time spent wrenching is time not spent riding and 2. I cringe a little every time I knock a PF BB out of a plastic frame. And 3. I like products that can withstand the test of time. I recently installed a Chris King BB I had gotten for my Titus moto lite back in 06 on my Druid. Still works like a charm.

Reply

Andrew Collins

1 year, 11 months ago

I've had a BSA Ultegra BB go for over 10,000 KMs on my road bike. Not super cheap but a fraction of the cost of a CK bb.

Reply

Andy Eunson

1 year, 11 months ago

You’re right Mr Ferrentino it’s not press fit per se but poorly fabricated bb shells that create problems. I’m convinced my previous bike had an out of spec threaded bb. It had various bsa 30 bbs in it which lasted half a season or less before creaking started. Removal and cleaning would solve that for a short time period but then one bearing or the other would have a click when turned in my fingers. I’ve had three press fit bikes. The road bike never had any bb issues nor has my Trek Remedy in three seasons. The cross bike did. One riders experience with a number of bikes isn’t statistically significant of course but my feeling is that it’s manufacturing tolerance issue.

Reply

Mario S

1 year, 11 months ago

$230 for a BB with the promise of reliability? Ive spent a lot more on stupid unnecessary things

Reply

Andrew Collins

1 year, 11 months ago

For true min max though you could get a Ztto BB and some NTN or NSK bearings and get 95% of the performance for less than half the price.

Reply

AverageAdventurer

1 year, 11 months ago

Hey NSMB someone tell me how enduros new MaxHit headset/bb is! I can't seem to source them anywhere and they make some pretty bold claims in performance and warranty. While I can get down (and have) with xd-15, if I can cram in a maxhit for a fraction of the cost and get similar results I'm all there.

Reply

Cam McRae

1 year, 11 months ago

We'll see what we can do!

Reply

Andrew Collins

1 year, 11 months ago

The $230 question is whether these fancy XD15 bearings have a longer/better service life than the fancy SKF MTRX solid oil bearings or Chris Kings. Although in fairness there probably isn't much of a price gap between the three.

Reply

shapethings

1 year, 11 months ago

I ordered a new BB a few hours ago to replace the Cane Creek Hellbender Neo with those fancy SKF bearings. CC discontinued selling bottom brackets with those bearings.

The bearings still spin, but it feels like you're trying to run in quicksand. No grinding or similar sounds you get from a conventional compromised bearing, just friction.

Can't remember where I saw it, but think those type of bearings are now being used for pivot bearings instead — which they're better suited for versus the constant rotation of a bottom bracket.

Reply

Andrew Collins

1 year, 11 months ago

Interesting. The concensus recommendation around here is to go with the Enduro Max bearings for pivots.

I wonder how the MTRX bearings would go in wheels?

Reply

hongeorge

1 year, 11 months ago

See above, I think Cane Creek discontinuing them in BBs is telling. Such a shame, I thought they would be a godsend, but it was too good to be true.

Reply

AverageAdventurer

1 year, 11 months ago

I got a 110 CC hellbender bb just this past year and there new units run these xd15 bearings as well! So far so good...

Reply

JT

1 year, 11 months ago

Normally I'd opt for King, but they no longer produce any pressfit BB's. Here's hoping that changes before I have to swap mine out.

Reply

Sethsg

1 year, 11 months ago

I am trying to replace my BB right now It's so worn out that the crank spindle just spins inside without the bearings turning. Sadly, it's press-fit, which means I don't have the tools and will need to pay a shop $30 just to install it.

Reply

Deniz Merdano

1 year, 11 months ago

Lucikly Press-Fit BBs need less tools than Threaded BBs. A punch and a mallet will get you through, and if you are not careful, through your frame. a wooden dowel will also work punching them out.

Reply

kcy4130

1 year, 11 months ago

Well technicallllllyyyy, a press fit bb requires more tools. Threaded requires the special wrench, just 1 tool. Press requires a hammer and a punch, so 2 tools! Hehe, sorry I just couldn't resist being a pedantic ass.

Reply

Deniz Merdano

1 year, 11 months ago

I know where you are coming from but when I think about all the Threaded BB tool interfaces, i want to drop everything and pick up running.

Reply

Perry Schebel

1 year, 11 months ago

i'd be fine with using a rock & a stick to remove & install my pf BB's (if i didn't already have a BFH & random big bolt kicking about); effectively tool free!

i actually prefer pf; fast in & out, nice simple & wide interface, problem free (on the last couple bikes i've owned, obviously others have had different experiences). really, bb's should consist of nothing more than standard bearings pressed into bb shells.

Reply

taprider

1 year, 11 months ago

I have the tools to remove and fit a press fit BB.

I had an XT BB put in at a LBS while my Chris King was sent off for replacement.

When I got the Chris King replacement, I went to remove the XT with proper tools, and one cup is stuck in so tight, that even with some bracing under the frame, a big hammer won't remove it. I will need to make some kind of support that fits closely around the BB shell, so that I can use a sledge hammer without making the frame flex

Reply

Kenny

1 year, 11 months ago

If it was at sledgehammer level I'd be breaking out the Dremel.

Reply

Sethsg

1 year, 11 months ago

Just a question how do you get the BB out once you install it? It's great that you don't need a tool to install it but what about taking it out?

Reply

Andrew Collins

1 year, 11 months ago

For true pressfit you can either use a brass punch and rubber mallet, or there are specific tools that use an expanding collett to either punch or drive them out.

The BBs that screw into themselves usually use a specific bb30 wrench or socket.

The Hope pf41 has a very specific tool. But the f41 is a super duper secure BB that will cure creaking in most press fit bikes.

Reply

LWK

1 year, 11 months ago

Enduro's claims sound/smell like the usual bike industry nonsense - 99%+ marketing drivel and a wee bit of pixie dust sprinkled on a gullible market. From the little bit I've learned about bearings along with a couple of interesting Hambini articles my take is that its difficult to make really high quality bearings. So the odds that Enduro knows more and can do a better job than large dedicated manufacturers like NTN/SKF/FAG is virtually nil, IMO.

As for the ceramic bit... Hambini had an interesting article with some data showing that while ceramic balls may start out smoother, as long as they are harder than the race, they will wear the race and you'll get poorer performance than regular old steel balls sooner than later.

Reply

Bogey

1 year, 11 months ago

One thing to remember about bicycle bearings is that they are very lightly loaded and usually fail from corrosion and not from overloading. Good, corrosion resistant bearings with good seals and good grease are always the best choice. Bearings with high load ratings and high speed ratings aren’t needed for bikes so Hambini’s observations are 100% incorrect.

A good engineer can design something that will be very good for its intended use. The big companies such as SKF & NTN can surely design and manufacture good bearings for many industries but do they know bikes? The fact that SKF sold that solid lube bearing to Cane Creek for use in a bottom bracket tells me that they don’t know bike bearings (and It is disappointing that Cane Creek didn’t know better either).

Reply

Zayphod

1 year, 11 months ago

Everything from Enduro is overpriced piece of junk.

Reply

Pete Roggeman

1 year, 11 months ago

That seems like a rather random and vague remark. Care to elaborate or are you just here to be snarky?

Reply

Zayphod

1 year, 11 months ago

That's just my personal experience with Enduro LLU Max and bearings from other companies (NSK and Koyo, both of which are cheaper).

Here's a few pictures for the curious.

The Enduros were full of dirt, the grease have been washed out, the balls were rusty and overall the bearings were barely rotating and skipped a lot. On the other hand, the NSKs and Koyo' are like in the day I pressed them in.

If you look closely, you can see the massive groove in the inner race of NSK. And you really need to apply some force to put back the seal. The same goes for Koyo. Enduro have much smaller groove and you can take off/put back the seal with no effort at all.

Downvote me as much as you like, people, i'm just sharing my experience with Enduro. But if you make the effort and do some research, people are generally not happy with them and recommend bearings from companies like NSK, NTN, FAG, SKF.

Reply

Pete Roggeman

1 year, 11 months ago

That's a legit complaint but your experience with one single Enduro product makes your opening statement both over-generalized and far from accurate. If we all only gave a brand or product one chance before writing them off completely, there wouldn't be a single product available for sale.

Reply

Zayphod

1 year, 11 months ago

Technically I tried 2 products and gave em 6 (4x6001 + 2x608) chances.

They are expensive and they suck compared to bearings from other brands.

The end.

P. S. I wasn't aware that they make other stuff besides bearings. Now I realize that my first comment is inappropriate. I'm talking only for their bearings.

Reply

irck

1 year, 11 months ago

I’m just about to replace the rocker pivot bearings in my 2020 Norco Optic. Are the NSKs and Koyos full compliment bearings?

Reply

Zayphod

1 year, 11 months ago

The ones I bought have a cage. You'll have a hard time finding full complement bearings from the big brands. I don't know much about bearings, to be honest, but I doubt you'll be able to overload a standard caged bearing.

The biggest enemy for a bearing is water ingres, so tighter tolerances and better seals are more important than bunch of extra balls.

Reply

YDiv

1 year, 11 months ago

Where did you source the bearings from? Also curious how much the price difference is. I'd expect them to be more expensive but seems like that information is a little bit sparse online.

Reply

Zayphod

1 year, 11 months ago

If I can't get the locally, then I order them online.

The 6001 Enduro was ~6.05usd a piece. 6001 NSK was ~3.82. (2019 prices with 1:1.75 exchange rate applied)

And since nobody was importing Enduro in my country, I had to order them internationally, which made them even more expensive.

Reply

Please log in to leave a comment.