Review, Interview and Product Intro

Introducing PNW Carbon Handlebars

The hot topics with carbon handlebars these days are comfort and compliance. I haven't recently heard anyone complain about a lack of control or stiffness, although I'm sure there are some burly riders who have experienced that. The tricky part about compliance is that you don't want it in every direction. If the bar deflects moderately, and in-line with the angle of forces received vertically from the wheel, that should improve comfort and reduce fatigue. If the bar deflects fore and aft, that could compromise precision when cornering, navigating a rock garden, or rolling off a ledge on an angle. OneUp tackled this issue by ovalizing the external structure of their carbon handlebars. They look a little squished in the central portion on either side of the stem so optimize stiffness and compliance in different directions.

I chose a higher rise bar for a change to use on bikes with short headtubes.

Indicators to help you cut your bars to your preferred length. Founder Aaron Kerson told me that that portion of the new bar has been altered for this purpose; "If you're going to trim your bars, we're using just a standard checkered style of carbon there because you can get a nice square cut."

PNW Components had similar ambitions but they instead decided to alter the interior form of the structure to achieve a similar balance of comfort and control . I haven't yet seen an image of a cutaway bar to display this but the animation below gives you an idea of what is going on.

The complete package.

Range Stem Gen. 3

The latest version of PNW's Range stem is easily installed, includes a GoPro mount that can be added to the faceplate, and uses quality hardware. It clamps simply with the bottom of the faceplate closing completely and the top with 6n/m of torque.

The third gen. of PNW's Range stem allows for a GoPro mount on the faceplate. It's not a quick on/off though. The faceplate must be removed if you want to remove or install the mount. Or you can just leave it on full time.

It's a pleasing and solid looking piece that feels reasonably light. I didn't weigh it and couldn't find that info on the PNW website. It's available in 40 and 50mm lengths and either 31.8 or 35mm clamp diameters.

Features and Specs

The bar is light, at 233 grams, comes uncut at 800mm and sells for 149 USD. The graphics are embedded in black from the factory but then you can choose from 10 different packs of coloured sticker packs to dress it up if that's your thing.

PNW Carbon Handlebar Specs. provided by PNW

- MSRP: $149 USD

- Decal kits sold separately for $5 USD

- Specs:

- 800mm width

- 35mm clamp diameter

- 38mm or 25mm rise

- Weight: 233g

- Upsweep: 5°

- Backsweep: 10°

- 3rd party test lab certified as passing the most stringent global testing standard for bicycle equipment; EFBE’s Tri-Test® for MTB Gravity Category 5 - rated for e-bike and downhill riding.

- The Loam Carbon Handlebar comes stock in Cement Gray, with decal kits available in 9 signature PNW colors: Safety Orange, Black Out Black, Moss Green, Moto Green, Pacific Blue, Fruit Snacks, Really Red, Seafoam, Teal, and Peanut Butter

The applied graphics give you lines to aid in clocking the bar, but unlike OneUp's effort, there is no guidance for clocking based on the geometry of your bike. I was told this wasn't hyper-critical and that there is a range of bar roll positions that should provide the benefits of the internal shaping.

Bars displaying applied graphics.

Ride Impressions

Many factors can influence your impression of a handlebar and its relative stiffness; temperature, fork settings, tire pressure, grips and even existing hand fatigue from a previous ride. There's no perfect way to control for every factor but I rode a similar ride on consecutive days to get my impressions. I've been riding and enjoying OneUp's Carbon Ebar, cut to 760mm, so I put the PNW bar - also cut to 760mm, along with a PNW Range Gen 3 stem, on my Norco Sight VLT and removed the corresponding OneUp bits.

There are moments when having confidence in your handlebar is essential. Or your handlebars. Photo - Craig Cameron

On my first ride on these handlebars, it was a cool day and the ground was firm but not frozen. I realized later that, rather than swapping to the PNW grips I should have removed that variable and continued with the existing ones from Loamlabs which are nicely broken and as a result likely provide less cushioning. There was no going back unfortunately.

I was riding with my buddy James Wilson and we were pushing hard on our descents and riding long sections of trail before taking a break. I experienced some hand fatigue that seemed normal because of the pace and intensity of the ride. Control seemed excellent and I was having a very good day on the bike.

On my second ride, with a keen but less experience rider friend which led to more breaks. On this ride I had no hand fatigue at all and the bar was essentially invisible. I noticed no improvement over the OneUp but also no increased force transmitted to my hands from trail impacts.

As an aside, I am curious about how handlebars that were designed and laid for specific widths below 800m and perhaps with weight limits. It doesn't seem to make sense that we are all riding handlebars designed to work for someone who is 6'6" tall and weighs 260 lbs.

A PNW future planning meeting in Santa Cruz, with riding included. Founder, Aaron Kerson, is third from the left in the back row.

Interview with PNW Components Founder Aaron Kerson

Cam McRae - Tell me why this was the right time to launch a new handlebar for you and why the world needed one.

Aaron Kerson - Our debut was an alloy handlebar. That's something I really feel strongly about. I think there's a lot that can be done with alloy between the actual material properties as well as the butting profiles and even just down to the geometry of the bar. So that was an area that we really wanted to focus on. We've had great reception with that bar. For me, a 31.8 diameter alloy bar is pretty awesome, like very bomb proof and also gives a nice bit of compliance. So I was very happy with that. We got a lot of requests though for carbon bars, like a tremendous amount over the years. The issue I had was I didn't want to just enter in the market with yet another carbon bar. But now that we've built out the team and we've got a full product department there, we all felt the same way; we're going to wait until we really have something that's truly special, a really special idea that we can build off. And until that time comes, we're not doing it. So that was, that was why it came about. I mean, as you know, carbon is such a cool material because you can do so much more than you can with alloy. And that was a really, a big reason for us is just figuring out why.

Product developer Steven Lin doing some testing in Taiwan.

I assume it's produced in Asia.

Aaron Kerson - Yeah, so we chose Taiwan. Most carbon is usually Southeast Asia, so places like Cambodia, Vietnam, Thailand, Indonesia. Well, not so much Indonesia, but those other three countries, and then obviously China.

A big one for us that we like to keep everything in Taiwan that we're manufacturing. The cost to do carbon fibre is substantially more in Taiwan, but you can find really nice boutique houses that do really high-end stuff and, there's a general statement like every factory is different, but there tends to be more of an infusion of manufacturing technology compared to what you can find elsewhere. Again, it's not that you can't find it, but our factory weaves their own carbon, they have their own loom. It's like a fabric loom. They actually are weaving this in-house. They then take the sheets and they actually create them on demand. They're only going to create the carbon they need for the upcoming production batch.

That's impressive.

They then keep it stored in a refrigerated and climate controlled environment. This place is really kind of next level from that standpoint. So the carbon is really fresh. Believe it or not, carbon does go bad and it gets more brittle as it's exposed to, UV and various other elements out there. So that made us feel great.

They also can do EPS molding. And that was huge for us, right? Because the one downside with carbon fibre is, as you're putting the layup into the mold, you know, you're placing these sheets in there, you're painting on the resin and what can happen is, once you go to bake this thing, you have to support it from the inside out so that the sheets don't just kind of crumble on themselves. Think of, you know, when we used to make like paper mache, you would always put them over a balloon when you were a little kid, you know? So it's kind of the same type of process. So what a lot of factories use is an internal bladder. It's basically just like a bag that they puff up with air and it's pushing the carbon into the mold. The problem is ,the bag gets wrinkly on the inside, right? So you're getting these inconsistent layers of resin and carbon where the outside looks beautiful, but the inside is just like a craggly mess. You can't control wall thicknesses and so you're gonna get an inconsistent ride feel, right? Like some bars are gonna be crazy stiff, some are gonna be less so. And so what EPS allows us to do is, it's basically a firm inner, almost like a dowel that you put on the inside of the carbon. It allows us to do completely smooth inner wall shaping.

We filed a patent for this, where it's a combination of the way we're doing the layup, as well as the inner shaping of the bar. And that allows us to build in certain ride characteristics in the bar, which we felt were really important. And then also keep other areas stiff that we also felt were very important to control. So that, so all of these things together allowed us to do some really cool stuff out of Taiwan.

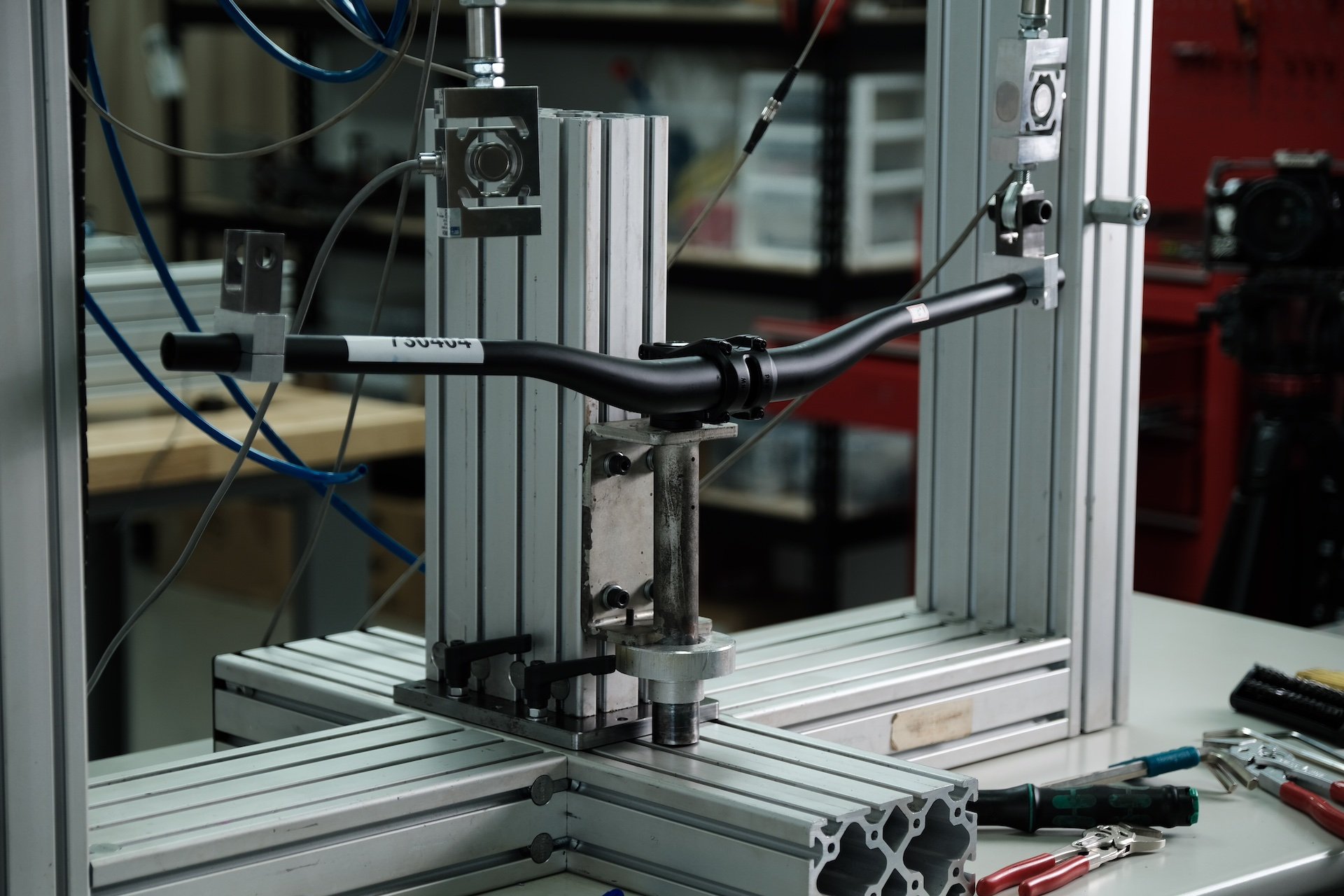

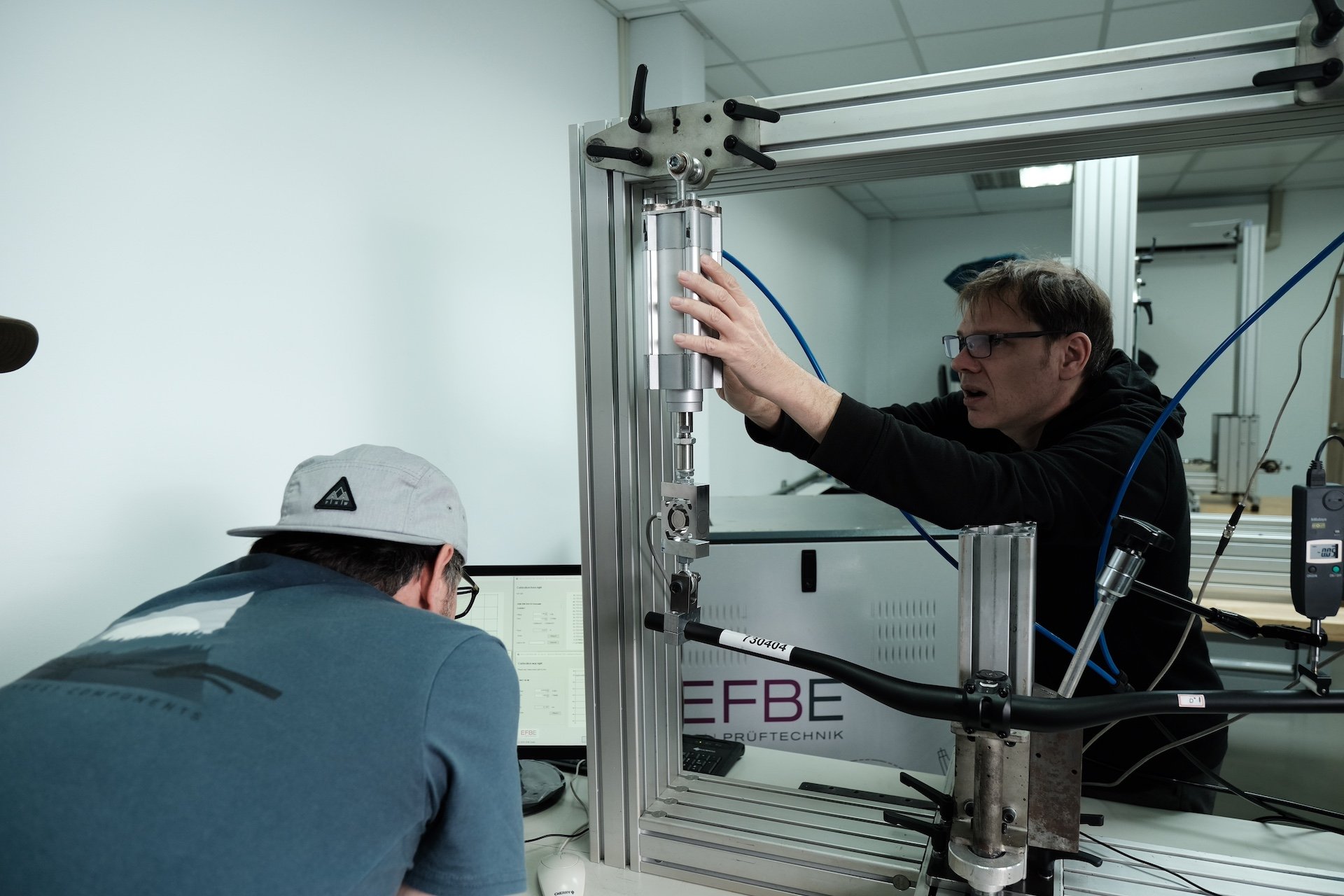

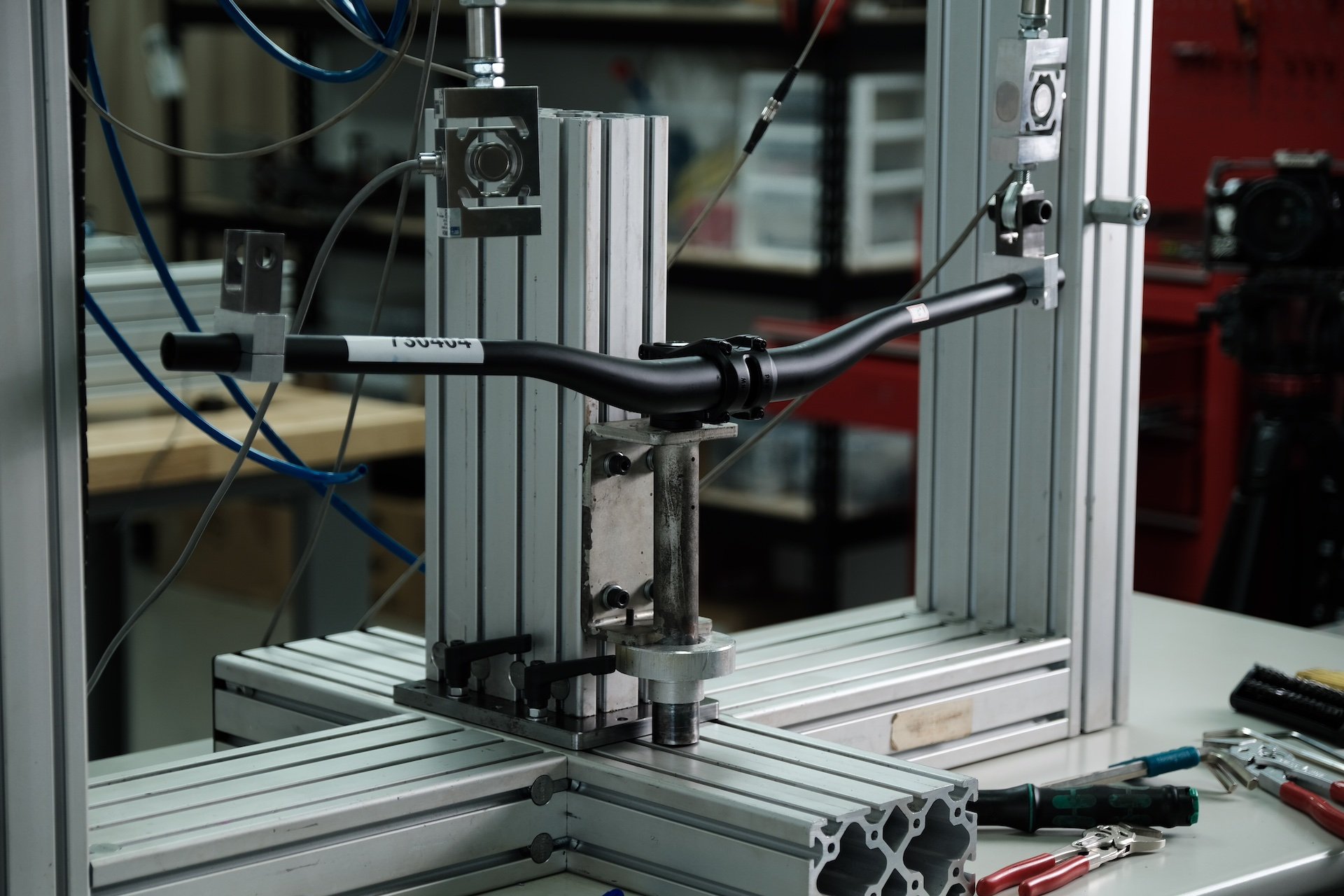

PNW engineer Joseph Solomon along with an EFBE test engineer conducting fatigue testing to EFBE’s Category 5 Gravity Standard

The differences on the bar are, a lot of them are on the inside?

It's essentially an ovalization in certain areas of the bar. You've got the flat belly of the bar with the stem clamps and then it tapers up. We've actually controlled the wall thicknesses through that section and created an essentially an ellipse that's on the inside there. We wanted to control for integrating vertical compliance. So that gives you a nice hand feel. But as you dive into a corner, you want that horizontal stiffness, because what happens is we tested a lot of other bars on the market and while they may have had decent compliance, we felt they were really unpredictable. Like when you'd be coming through a really chattery section, the bar is moving around like this in all different directions, the front wheel is then able to move someone independently from that. And so you just don't feel as confident.

As you're diving into a G out into a corner going off of a lip I mean, you know The bike is moving around under you in ways that we really didn't feel comfortable with and didn't really appreciate So that's where the combination of these two elements of the layup as well as the ellipse allowed us to do exactly that. We then did a ton of FEA on the computer but then actual real-world Bench testing to validate our thesis and then combine that with ride testing.

Can you tell me about your ride testers? Are they all in house? And what testing methodology did you use.

No, it's a combination. We actually sent these out globally as best we could just to get a variety of feedback on various types of terrain. So we have folks basicallynfew different areas in California. We have people in the UK. We have people up here, you know, Seattle area, I guess just across Washington. We got some folks on the East Coast, so Asheville, North Carolina area that are riding there, as well as down in the Southwest, you know, in the really rocky areas, you know, Sedona, Tucson-ish type of area. And then we wanted folks that are just totally unrelated to us. So a combination of like shops we work with, other just kind of local recommended riders that have experience with testing product. So we really wanted to get as much unbiased feedback as we could.

We brought out bars with different on the inside that we wanted to test. And we just, we just labeled them like gold, silver etc., just very generic names so that people didn't know, except for our engineer, no one knew what the shaping was, right?

What was the response from testers?

The feedback globally was all unanimous, which is wild that the shaping we ended up choosing was better riding than various other shapes we did. So that was unexpected, to be honest, but that also was a huge validation for us that, like this is not placebo, right? Like this is a real thing that people are not just feeling, but also preferring. So that was very cool.

After blind testing, what was the next step in the process?

We then validated that with bench testing. We set up a rig where the bar is clamped into a stem onto a very fixed bench, and then you're able to hang weights off the end of it, various kilos of weight, and then you measure how much deflection there is. We did that in-house, and then we also contracted with a third-party lab, EFBE. They're very well known for specifically bicycle, frame, and handlebar testing, going above and beyond what ISO requires for testing. They're a lab out of Germany, and had them do not just our strength testing, but also validate our deflection testing as well, and the results were consistent. So that was huge for us.

More fatigue and load testing.

I have more of a general bar question. These are obviously tuned to feel right at 800 millimeters for heavier riders* who like a wider bar generally. I usually run my bars at 760. Obviously you have less leverage. For a rider who often weighs less than the rider on the 800mm bars, how much impact does cutting 20mm of each side have one bar feel?

*That's a generalization that I'm sure doesn't hold universally and I realize there are lighter riders who like 800mm bars.

That's true with any style of handlebar, even if there's butted tubing on an alloy bar, for instance. Yeah, the more you cut it, the less leverage you have. So what we've been doing is actually testing those exact values in-house. So we should have those ready to go, I believe around time of launch.* So we're just seeing what the impact is, just so we can make recommendations to folks of just like, this is what's to be expected essentially.

Ecommerce Program Manager Brandon Fuller (left) & IBD Sales & Events coordinator Katy Tarr doing some beer testing.

*Unfortunately this data isn't yet available

Were you and the other testers surprised by how much difference you noticed between different bars?

We were, and that's something I think that is really important, regardless of what bar you're riding or going to buy as a rider. Like carbon.does not mean carbon, the same thing across all applications, right? Like some applications of carbon, like you're going to use it in aerospace for certain reasons, you're going to use it in medical devices for other reasons. And then bikes, like you have a wide array of what carbon actually means. And that was something just kind of rewinding thinking back to when we all started to first see carbon on the market. It was all about weight and then it became weight and strength. And then it became weight strength. And, you know, you can build in ride characteristics and now it's all about aero shaping, right?

So there’s a lot of things you can do with carbon. That was fascinating. So seeing this display of how these bars actually shaped out, it was really interesting to us just kind of like if we were customers out there buying a bar, super confusing right? Like there's not a lot of data around what all of these bars actually mean and what carbon really means. Like you may be like, oh I want carbon because I assume it's lighter or I assume it's better, but I think a lot of riders maybe are buying based off brand and other recommendations. And the fact that all of these bars are super popular and they all were different, I think everyone's experiencing things very differently out on the trail. It was fascinating.

After working with aluminum, what did you discover about the environmental impact of working with carbon and then having eventually to be disposed of?

Yeah, I mean what we found to be totally honest, it's not great, man. It's something that we all desire. We want the high-end light stuff, but the environmental impact is very real. One of the criteria for working with a factory was how they handle carbon, other disposing of chemicals. That's less monitored other regions where carbon's being manufactured. So the fact that we're in Taiwan, the environmental standards are much more stringent than other areas. So that was super important to us.

The recyclability standpoint. Yeah, I don't have a great answer for that. That's something that we're working with them on. And we're actually looking at making products that are made out of recycled carbon that they have excess of in their factory. You can take these extra sheets. and grind them up and blow them into an injection molding process and you can make all types of cool stuff.

Real world testing with TJ Trotter (Product Developer and Project Manager)

How important is clocking the bar precisely in order to realize the benefits of your design?

The way that we designed the bar is that it’s not going to ride poorly if you don’t have it rolled exactly to 10 deg back sweep. That’s a rider preference and the benefits of the design still provides the intended vertical compliance even if it’s rolled a bit more forward or back if that’s what the rider wants. The bars at are designed around modern trail and enduro bikes with HT angles 64-69 degrees and neutral bar roll roughly parallel to head tube angle so if you’re outside of that then sure, you might feel small differences but it’s not like the bar is going to be a jackhammer suddenly even in that scenario.

You're making one handlebar to start. Who is who is this handlebar for? What kind of rider?

So we're starting with 35 millimetre diameter and we've got 25 and 38 millimeter rises. Obviously this is a trail focused bar. It is tested at a category five gravity standards. So this thing is approved for heavy e-bike usage, downhill riding, all of the gravity aspects. So really, you know, this is a rowdy bar.

I mean, this is for the rider who's out there on their enduro bike, trail bike, ripping trails, obviously you can do the bike park as well. Not to say this isn't a down country bar, it absolutely is. And we've hit a pretty aggressive weight target. But when developing it, we wanted to have that rider in mind, just cause the forces and the abuses are so much higher than other types of riding.You're going to get the same benefits regardless, but we were aiming more toward gravity focused riders.

My final set up with PNW Loam grips (which come in regular and XL sizes) and a gen. 2 PNW Loam Dropper Lever.

Conclusion

Your bars, like your cranks or pedals or seatpost, shouldn't be noticeable at all if it suits your size and weight and riding style. If it is making you aware of something that's generally a bad thing, like excessive flex or unwanted feedback from the trail.

PNW's new carbon bar was both comfortable and precise at 760mm and it seems like a bar I could happily ride for a good long time.

Compared to the bar I swapped out in favour of this one, a OneUp Carbon E-Bar, it's 16g lighter, has 2º more sweep at 10º, and more rise at 38 vs. 35mm. I didn't notice any of these changes having an impact on my ride at all.

Height - 6'/183cm (mostly legs)

Weight - 170lbs/77kg

Inseam - 33"/84cm

Ape Index - 0.986

Age - 57

Trail I've been stoked on lately - Lower Digger

Bar Width - 760mm

Preferred Reach - 485-500mm (longer with 27.5 wheels than 29)

Comments

Kyle Smith

2 months, 1 week ago

> For me, a 31.8 diameter alloy bar is pretty awesome, like very bomb proof and also gives a nice bit of compliance.

Yup, totally this. The PNW alloy bar with a 31.8 diameter is my go to bar. Functional, good value and reasonable weight.

I like 10 deg backsweep that comes on these bars. I have a theory that as bar widths get wider, the backsweep should increase as well. As an extreme example, imagine holding a broomstick like it was a 1200 mm bar, pretty uncomfortable wrist angle. It'd feel much better if you could rotate your wrists 20 degrees or so. Now if you hold that broomstick at say 550 mm, the zero backsweep feels okay. One of these days I'll get around to trying a true 'alt bar', but for now, I'm pretty happy with the PNW alloy 31.8.

Reply

fartymarty

2 months, 1 week ago

Try an SQ Labs aluminium. They have a really nice flex and you can roll the 16 degree bar so it has a nice upsweep.

Reply

Cooper Quinn

2 months, 1 week ago

https://nsmb.com/articles/pnw-components-range-gen-3-bar-and-stem/

Reply

Andy Eunson

2 months, 1 week ago

I’m sceptical. It’s impossible to say one way or another without actually flex testing a bar at different lengths and weight applied to determine if the compliance is good bad or indifferent. A bar is part of a system of , grips, fork, tire arms etc. Making various flexes makes sense to me. When I buy cross country skis they come with a flex test sticker telling me the weight range for the ski. I weigh about 65 kg and run a 760 bar. I think at my weight and bar width compliance is much less of factor than for someone that weighs 80 kg on an 800 wide bar.

I had a bar that was really soft. I could see the movement when I flexed it up and down mounted to the bike. It was a 3ttt Ergo something or other. Road bar. I don’t doubt that bars can be manufactured more or less compliant, but without some kind of flex number to guide us, you have to trust what? Marketing? I think compliant bars need to have some kind of weight range and be available in a number of flexes that they are tested to so a rider can determine what may or may not work for them.

Reply

Stephen

2 months, 1 week ago

Anecdotally, a local MTB company I worked for did back-to-back testing of 5 or 6 different handlebars on a local North Shore lap. One of those bars was the OneUp Carbon bar, and it was unanimously chosen as the most comfortable one. All other bars were found to be almost indistinguishable from each other. The other bars were a mix of aluminum and carbon.

The test was blind, the riders couldn't know which bar they were currently riding. There was also telemetry data recorded on the rider's person but I did not get to see that, just the written reviews.

Reply

fartymarty

2 months, 1 week ago

I would love to see some flex tests on bars to see which are more complaint. Maybe there should be a standard load / deflection test that manufactures could publish. Then you could pick a bar stiffness to suit rather than the trial and error we currently have.

Reply

Ride.DMC

2 months, 1 week ago

Just out of curiosity how did they disguise the bars to make them indistinguishable from one another visually?

I can tell the difference between my OneUp bar and Rental bar from across the room, let alone when I am holding onto them.

Reply

Cam McRae

2 months, 1 week ago

I would assume they covered them with something. Fabric would be my guess.

Reply

PeakHopper

2 months, 1 week ago

Wrapped them all up up with a bit of fabric and tape. Made it a bit of a hassle swapping all the controls and stem bolts.

Reply

Cr4w

2 months, 1 week ago

Every time this comes up I mention this and the herds of mostly identical medium guys say that weight and bar length have limited effect on flex and that we're all the same just like them so just why don't you shut up and be the same too.

Reply

Mammal

2 months, 1 week ago

I'm sure some people would be absolutely shocked how different bike frames and components behave under different riders, especially when overall mass is concerned. When the user group is spread between 130 - 220lbs, there's going to be a pretty wide band of performance variance.

Reply

BarryW

2 months, 1 week ago

While it's a good article, I'm a little surprised by how much effort and discussion there is over... Handlebars.

And although the interview was interesting I think we all need to realize that there is no recycling of carbon fiber. And while PNW is 'hoping' to make 'cool stuff' with downcycled carbon items they are just using the trash once before the landfill. Carbon fiber has a significant cost and it is not currently (or likely near in the future) reusable. So whatever greenwashing they do it's still the same story. Now aluminum in the other hand is aggressively recycled and continuously reusable.

As an item with a finite lifespan (as you noted above Cam) I find aluminum to the the only option for me.

Also, the eps wrapped carbon inside a mold is something I've seen in quite a few videos before. Mostly for other types of things than bicycles, but they can't be serious that it's actually a new thought can they?

Reply

cheapondirt

2 months, 1 week ago

I appreciate the 10° backsweep PNW uses. It seems carefully chosen to add a little comfort vs a typical 8° bar, without alienating anyone.

Reply

Cam McRae

2 months, 1 week ago

I’m (now) picking up what you’re putting down

As is often the case, I needed a swap back to my usual specifications to notice all the properties of the PNW bar. I liked the 10° backsweep but didn’t realize how much until I rode something a little different

I was on a size XL Arrival yesterday, with a We Are One 20mm rise bar and after the 10mm backsweep on the PNW bar, the WAO felt almost straight. The XL Arrival is a little longer than my reach sweet spot so I think I’ll swap the PNW over to the WAO and also compensate for the short head tube with the 35 mm rise. The rise will also reduce the reach a few more mm, with help from the extra sweep. I may have to order another PNW bar though!

Reply

Steven Hambleton

2 months, 1 week ago

I'm pretty tempted but I'm already close to my minimum reach limit.. Also my current bar is a 50mm riser.

Reply

ackshunW

2 months, 1 week ago

Looks like a fine bar, I prefer metal. I like PNW stuff and can appreciate the transparency they are giving about their factory/ production.

But please, does anybody really feel that their bars were ever waggling fore-and-aft enough, unpredictably, to the point you’re not confident about where you’re steering??

100% make them more compliant up-and-down, but….. in the act of riding a bike, a human is going to put muuuuuch more force into the bar in that direction (double? Triple? 10 times??). I think flexxy-steering bar is a myth.

Reply

Cam McRae

2 months, 1 week ago

From personal experience I’m with you but I’d bet there are outliers

It might be related to both weight and riding intensity. I imagine the forces a World Cup rider puts into his or her bars are miles more intense than your average rider. Now imagine a 220 lb rider who comes close to those levels.

Reply

BarryW

2 months, 1 week ago

That's an interesting thought experiment about world cup riders Cam.

Here's how I see it.

Any rider might put their maximum 'pushup' effort on any given intense segment. I know I do sometimes, you know, the moment you feel like you're getting compressed no matter how you push back?

Only a world cup rider who is physically stronger in that motion would be likely to be putting more force into the bar. Size and weight are really the players here. No way Nina Hoffman puts in anywhere near the levels some of the rippers on here do; simply due to her physical size and sex. So the idea that different riding needs different bars feels like a flimsy premise. But different weight (and sex) riders might want different levels of flex due to those factors.

Reply

Velocipedestrian

2 months, 1 week ago

I'm not seeing the difference sex makes here, beyond statistical differences.

A heavier, stronger human puts more force through their bike than a lighter, weaker one.

If you are a strong, heavy human (maybe with extra leverage - looking at Cr4w here) then you get annoyed things are noodly. If you're a lighter, weaker human, you get annoyed with companies touting compliance in products you find too stiff.

Reply

BarryW

2 months, 1 week ago

Sure, but take two 5'6' humans that both weigh 150lbs, one male and one female and in any case where they are both equally fit the man is stronger. So for a woman's bike you would likely want more compliance than for the equally sized male.

Really this is just another point to make that a large part of the industry is not well served as they only get smaller in so many instances, where instead they need smaller AND designed for lower overall forces.

Reply

Leerum

2 months, 1 week ago

I'm rocking a weareone da bar, enjoying it. Before that I had some 31.8 alu bar from a local company - the comfort difference was immense between the two, and I have bad shoulders and a wrist that let me know it.

While the weareone bar is great, as I am sure this bar/oneup is, I think that the alu bar was probably particularly bad and I suppose what I want to communicate with this comment is that a good quality handle bar can really improve your ride. Or at least not having an awful one.

Reply

Please log in to leave a comment.